Our Services

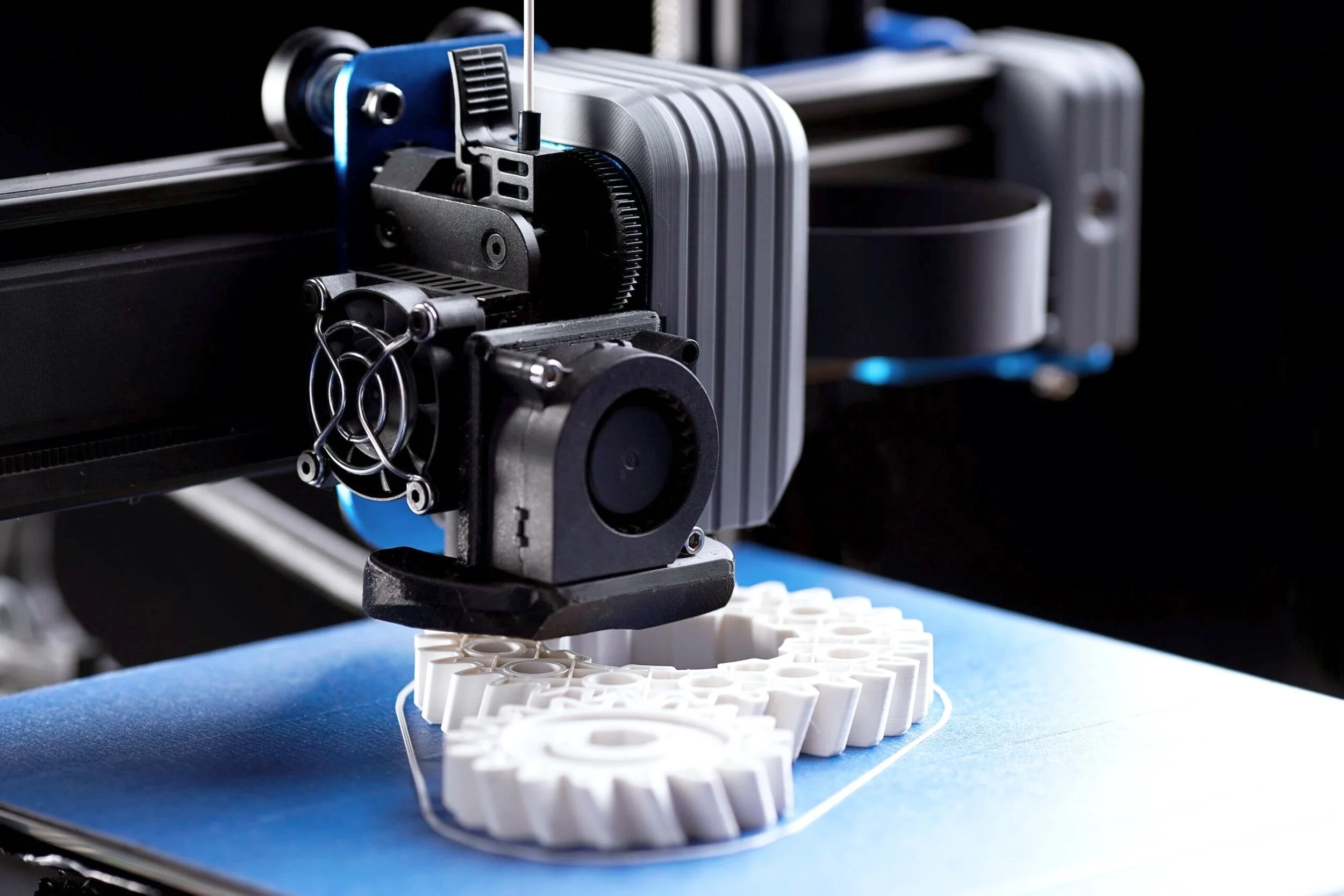

Fused Deposition Modelling (FDM) with Fibre

-

Fused Deposition Modelling (FDM) is an additive manufacturing process that builds parts layer-by-layer using thermoplastic materials. When combined with fibre reinforcement, it enhances the mechanical properties of the printed parts, making them suitable for high-performance applications.

-

Enhanced Mechanical Properties: By incorporating fibres, the parts exhibit higher tensile strength, stiffness, and impact resistance compared to standard FDM prints.

Versatility in Material Use: Ability to use a variety of thermoplastics combined with different types of fibres (e.g., carbon, glass) to tailor the mechanical properties to specific applications.

Cost-Effective Prototyping: Ideal for creating strong and durable prototypes without the high costs associated with traditional manufacturing methods.

Lightweight Components: The use of fibre reinforcement allows for the production of lightweight yet strong parts, beneficial for aerospace and automotive industries.

-

Thermoplastics (e.g., ABS, PLA) combined with continuous or chopped fibres (e.g., carbon fibre, glass fibre).

-

Aerospace components, automotive parts, custom tooling, and functional prototypes

-

Improved strength-to-weight ratio, enhanced durability, and high heat resistance.

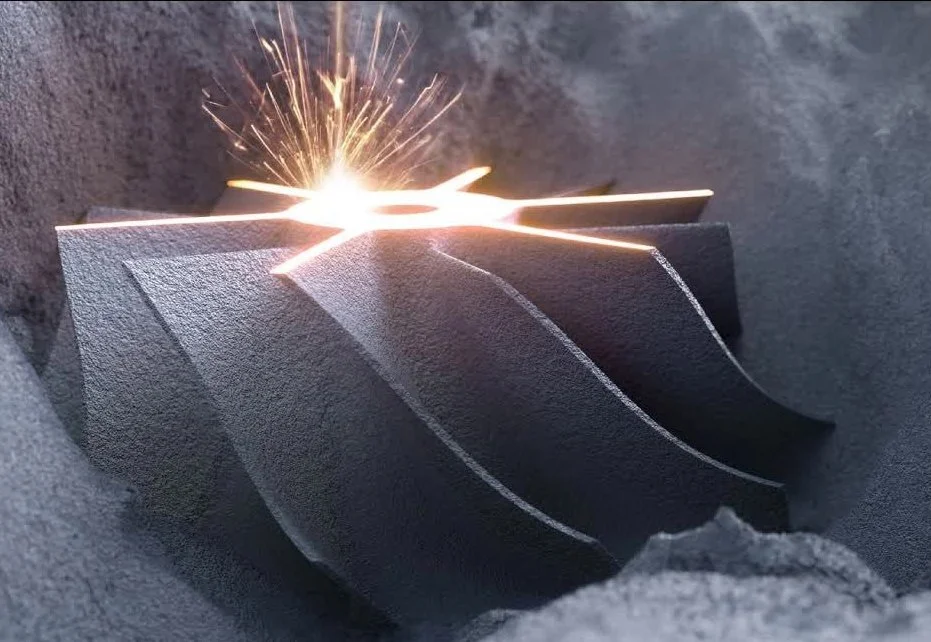

Selective Laser Sintering (SLS)

-

Selective Laser Sintering (SLS) uses a laser to sinter powdered material, binding it together to create a solid structure.

-

No Need for Support Structures: SLS can produce complex geometries without the need for support structures, allowing for more design freedom.

High Strength and Durability: Parts exhibit high mechanical strength and durability, making them suitable for functional and load-bearing applications.

Broad Material Selection: Ability to use a wide range of materials including polymers, metals, and ceramics.

Ideal for Functional Parts: Suitable for producing parts that need to withstand mechanical stress and high temperatures.

-

Polymers (e.g., nylon), metals, and ceramics.

-

Aerospace components, medical devices, consumer products, and functional prototypes.

-

High strength and durability, no need for support structures, and complex geometries.

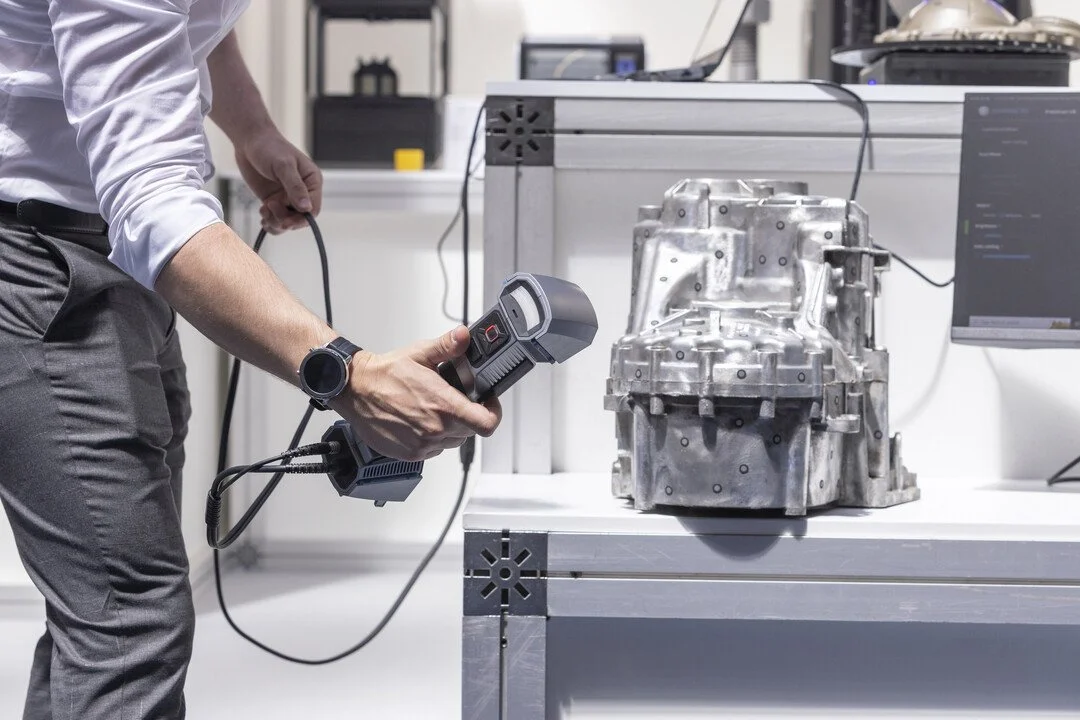

3D Scanning

-

3D scanning captures the physical dimensions of an object and creates a digital 3D model using laser or structured light technology.

-

High Accuracy and Precision: Captures detailed and accurate 3D models of physical objects, essential for reverse engineering and quality control.

Rapid Data Acquisition: Quickly scans objects, reducing the time required to create digital models.

Non-Contact Measurement: Suitable for delicate or complex objects where physical contact may cause damage or be impractical.

Versatile Applications: Used in various industries for purposes such as inspection, reverse engineering, and digital archiving.

-

Reverse engineering, quality inspection, digital archiving, and customization.

-

High accuracy, quick data capture, and the ability to scan complex geometries.

Stereolithography (SLA)

-

Stereolithography (SLA) is a 3D printing process that uses a laser to cure liquid resin into hardened plastic in a layer-by-layer fashion.

-

High Precision and Detail: SLA produces parts with excellent resolution and intricate details, making it perfect for detailed prototypes and models.

Smooth Surface Finish: Parts produced have a smooth surface finish, reducing the need for extensive post-processing.

Wide Range of Resins: Availability of various resins that can simulate different materials, such as clear, flexible, or high-temperature resistant resins.

Fast Prototyping: Quick turnaround times for producing high-quality prototypes, facilitating rapid product development cycles.

-

Photopolymer resins.

-

Highly detailed prototypes, dental models, jewelry molds, and functional parts.

-

High resolution and precision, smooth surface finish, and ability to produce complex geometries.

Vacuum Casting

-

Vacuum casting is a process used to produce small series of functional plastic parts by pouring liquid material into silicone molds under vacuum.

-

High-Quality Surface Finish: Produces parts with a high level of detail and smooth surface finish, closely resembling injection-moulded parts.

Cost-Effective for Low Volumes: Ideal for producing small batches of parts without the high costs associated with traditional moulding techniques.

Material Versatility: Can replicate a variety of materials and properties, including rubber-like and rigid plastics.

Fast Production: Quick turnaround time for producing multiple copies of a part, suitable for prototyping and short-run production.

-

Polyurethane resins and other thermoset polymers.

-

Functional prototypes, low-volume production, and replication of existing parts.

-

High-quality surface finish, cost-effective for small batches, and a wide range of material properties.

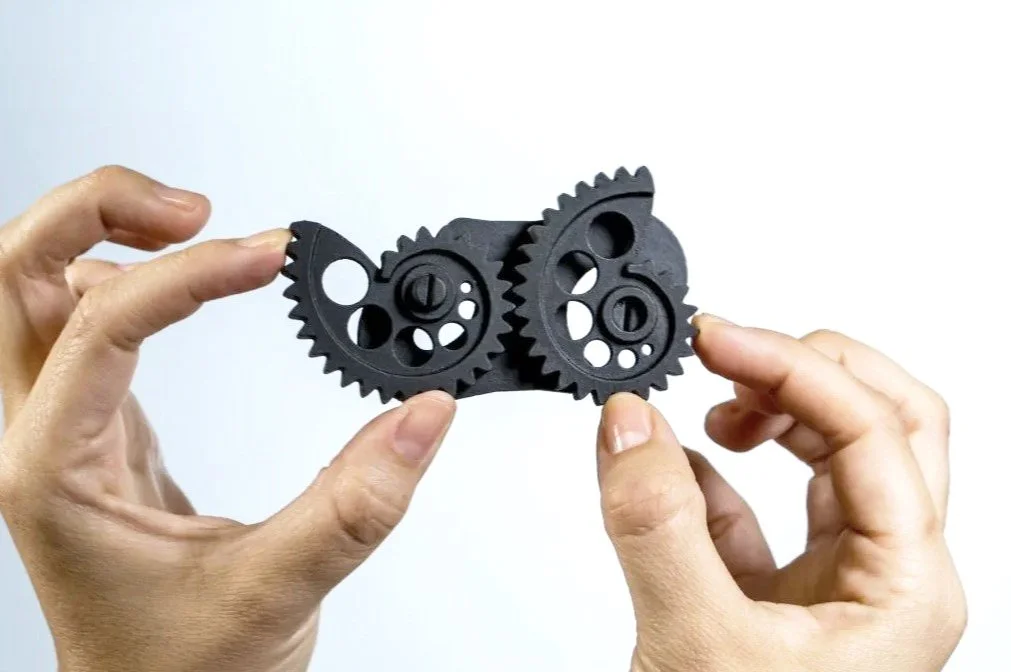

MultiJet Fusion (MJF)

-

MultiJet Fusion (MJF) is a powder bed fusion technology that uses an inkjet array to selectively apply fusing agents and detailing agents across a bed of nylon powder, which is then fused using infrared light.

-

Speed and Efficiency: Capable of producing parts at high speeds, making it suitable for both prototyping and low-to-medium volume production.

Excellent Mechanical Properties: Parts have uniform strength and are suitable for functional testing and end-use applications.

High Detail and Accuracy: Produces parts with fine details and smooth surfaces, reducing the need for post-processing.

Versatile Material Options: Compatible with a variety of polyamides and other materials, offering flexibility in application.

-

Polyamides (e.g., nylon) and thermoplastic elastomers.

-

Functional prototypes, production parts, and complex assemblies.

-

Fast production speeds, excellent mechanical properties, and fine feature resolution.

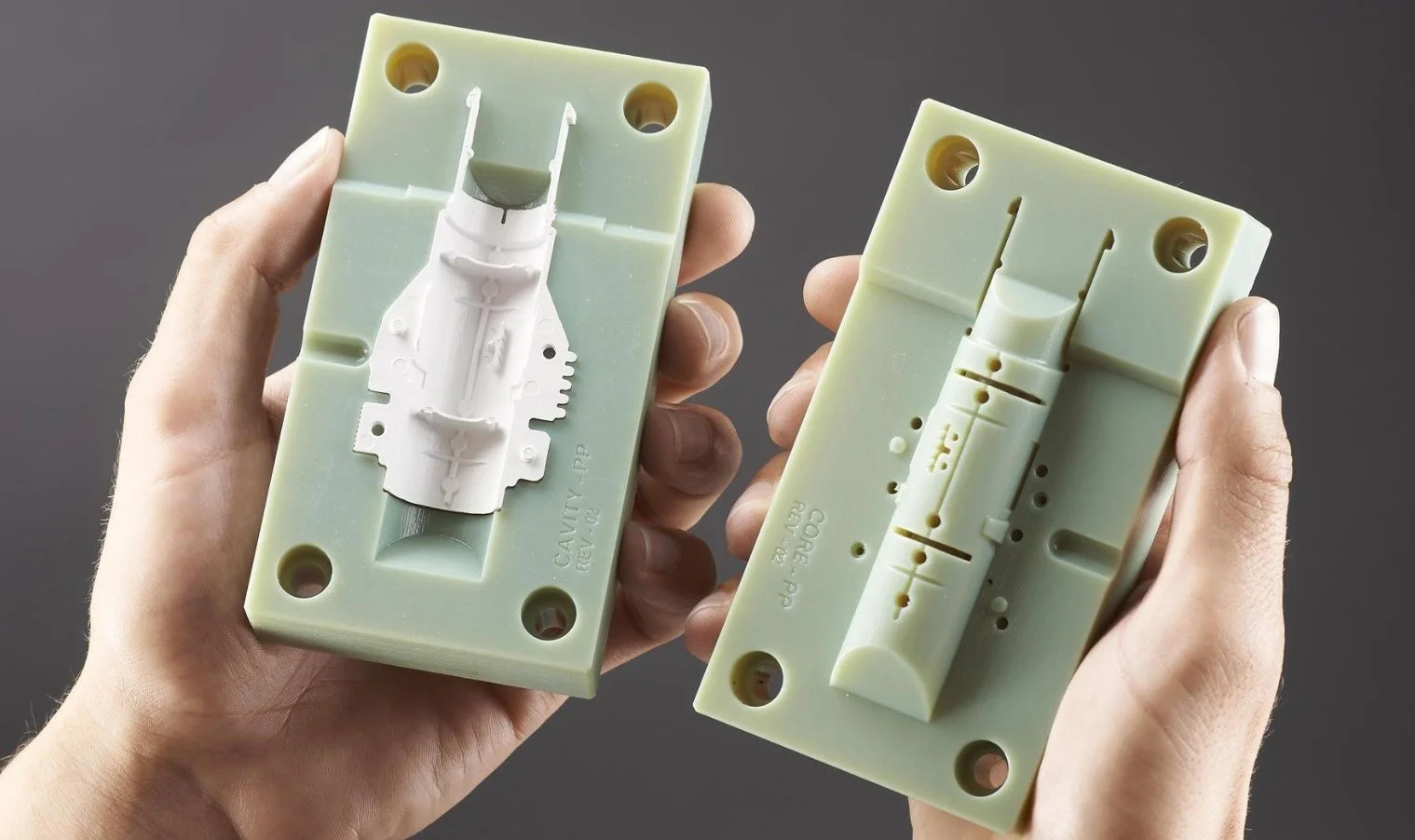

Injection Moulding

-

Injection moulding involves injecting molten material into a mold cavity to produce parts in large volumes.

-

High Production Rate: Capable of producing large volumes of parts quickly and efficiently.

Consistent Quality: Ensures uniformity and high quality across all produced parts, suitable for mass production.

Complex Shapes and Designs: Able to produce intricate and complex part designs with high precision.

Material Efficiency: Minimal material waste, as excess material can often be recycled and reused in the process.

-

Various plastics, metals, and glass.

-

Mass production of plastic parts, automotive components, consumer electronics, and packaging.

-

High production rate, consistent quality, and the ability to produce complex shapes.

Custom 3D printing is accurate to CAD

3D printing delivers fast rapid prototyping

SLA and SLS delivers good surface finishes

Strong, rapid prototypes and end-use parts

Complex geometry possible with 3D printing

Custom material supply services

Development of high-performance fibers

Development of high-performance plastics